Main Markets Served

PROTOTYPING

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

• Maxillofacial screens and cranial closure implants

• HTC grids

• X-ray collimators

• X-ray ID tags

• Anode and cathode grids for batteries

• Battery Contacts

• Electrodes

• Lead Frames

• Board Level Shielding

• Stents

• Vascular stiffeners and closures

• Haptics for intraocular lenses

• Screens for filtration

• Needles

• Fine Pitch Interconnects

• Surgical blade blanks

• Contact and retention springs

• Electrical interconnects

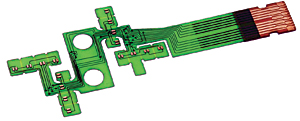

SG-Etch uses advanced manufacturing capabilities to deliver state-of-the-art flexible circuits for medical device applications, including implant, ultrasound, patient monitoring, and diagnostic medical electronics. SMT and thru hole component assembly services offer package sizes down to 0201 & .4mm pitch.

SG-Etch offers adhesiveless construction for thinner, more flexible circuits, and additive processing for higher density circuits with trace and space capabilities down to .0015" in production. Microvia sizes down to .001" diameter yield high density, multi-layer flex circuits. Alternate circuit layer materials such as beryllium copper, stainless steel and cupronickel can be used for optimum performance in unique applications.

From board level shields to BeCu contact strips to vents and filters, SG-Etch EMI/RFI shielding products are found in a variety of medical electronic devices and enclosures.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: Rm#911-912,Block 12, Huayao BLG, No.1 Pingan Road, Pinghu Town,

Longgang district, Shenzhen, P.R.China 518111

copyright@2007-2015@SinoGuide Technology Ltd.