SinoGuide always strive to be a leading manufacturer in the precision photochemical etching industry. Photo etching produces intricate components with exacting tolerances that are impossible to duplicate by other processes.

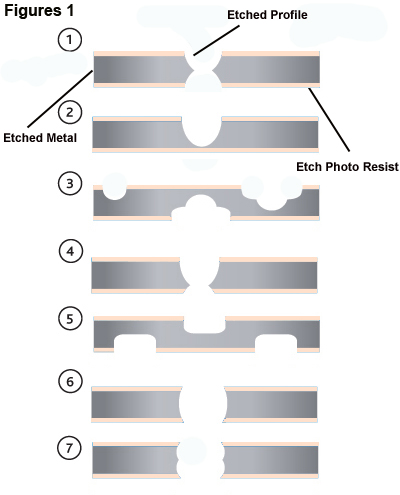

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process. The following guide gives practical limitations for chamfer, holes, spacing and construction dimensions with relation to metal thickness for photo chemical milling.

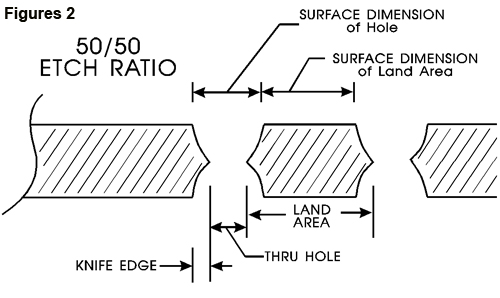

Metal thickness suitable for etching foils a few microns thick up to 2mm thick sheet (0.010 to 1.5mm). Thicker metals when etched will have a noticeable profiled edge “cusp” as detailed. Metals of any thickness can be surface etched.

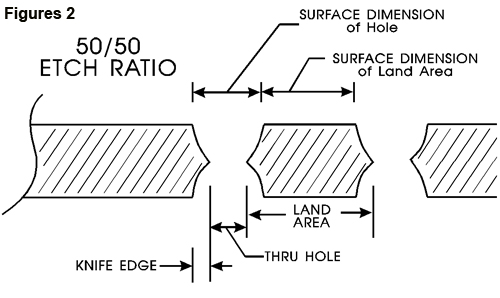

Dimensions as illustrated Figures 2

KNIFE EDGE BEVEL

KNIFE EDGE BEVEL

The smallest chamfer is proportional to the metal thickness, Always propose the Chamfer is less than 0.04mm. Consult us if a smaller or sharp chamfer is required.

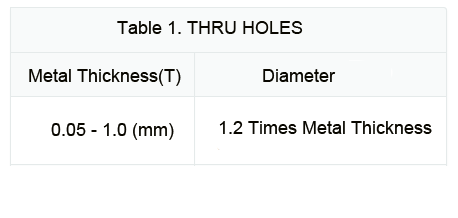

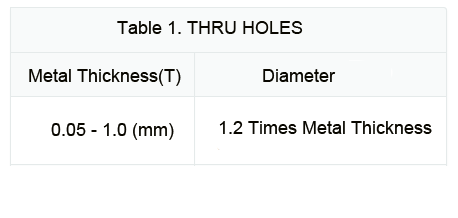

THRU HOLES

Generally, the diameter of a hole cannot be less than the metal thickness. This relationship varies as the metal thickness changes. A more exact relationship is illustrated in Table 1

.

.

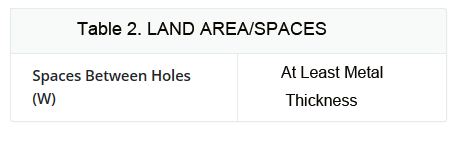

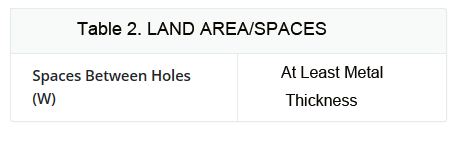

SPACING

Generally, the spacing cannot be less than the metal thickness. This relationship varies as the metal thickness changes. A more exact relationship is illustrated in Table 2.

Our photo etching parts best tolerances achievable are +-0.01mm on the flat profile size & +-0.10mm on formed dimensions. As a simple rule of thumb best tolerances offered would be 10% of material thickness. However often better tolerances can be provided if necessary, but please ask one of our etching sales team.

Technical Assistance

The photochemical machining process begins with experienced design engineers reviewing a part’s dimensions per customer drawing and then creating an AutoCAD rendition of the measurements in preparation for tooling. Our design engineer determines how many parts the sheet of metal can yield, and offers suggestions of how the part can be manufactured with the lowest tolerances within our machining capabilities.

+86-755-89375091

+86-755-89375091 Precision Photochemical Etching Expert

Precision Photochemical Etching Expert KNIFE EDGE BEVEL

KNIFE EDGE BEVEL .

.